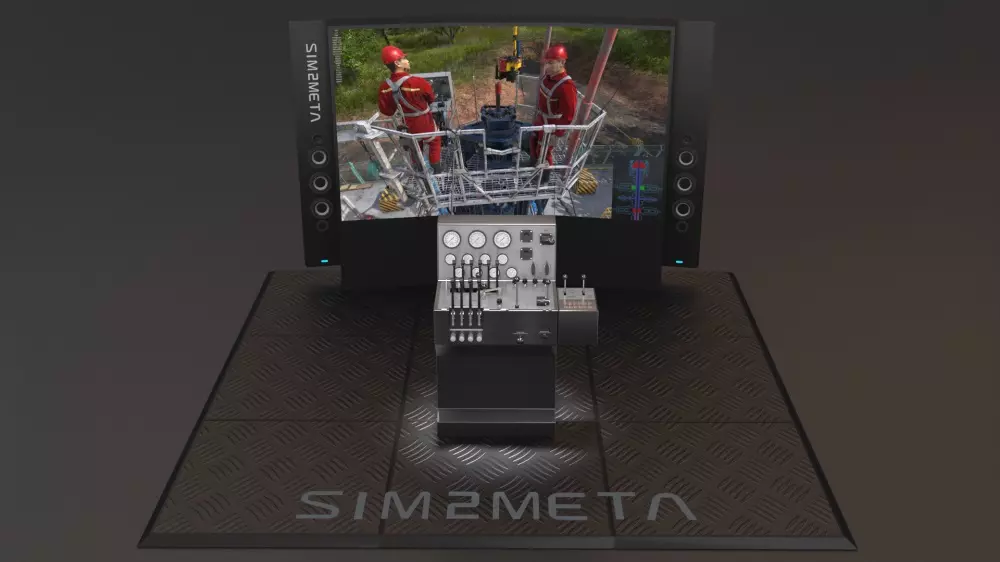

Workover Simulation Training System

Workover simulating training system simulates real field devices, which means layout of controlling panel, method of operating, way of parameter display are almost identical with operation site. Through synchronous 3D projection and lifelike environment sound, the systems produce visual effects which are very similar to real sites, and makes up immersive training environment. The system is based on advanced computer controlling, simulating, graphic and network technology combining with strict simulation of real drilling engineering process, which provides 6 categories, 35 training exercise in total, such as well killing, shutting in, etc. It is mainly used for operating training for technical staff working underground at oil fields.

Training Items:

(1) Primary workers operation

(2) Intermediate workers operation

(3) Senior workers operation

(4) Shutting in operation

With drilling platform

Without drilling platform

(5) Well killing

(6) Animation display

System Features

Parameters